|

June 29, 2007

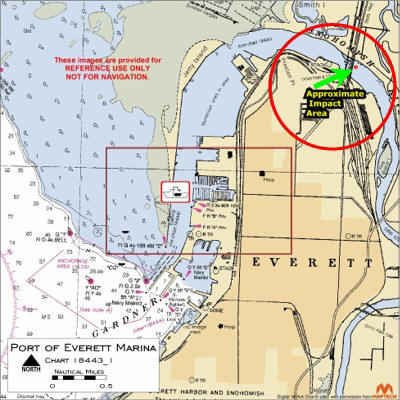

On the

weekend of May 17-20, Combatant Craft of America sponsored an

Armed forces Day event at Lake Union Park, Seattle WA. On

Tuesday May 22, 2007 about 14:30, during the return trip to our

moorage in Everett, WA we struck a submerged object immediately

after passing the Snohomish Channel Railroad Bridge and the two

State Highway 509 bridges. We were operating at an idle speed of

about 3 kts. Dan Withers was at the helm at the time of the

incident. The visibility was clear and the weather warm. The

river was flat and the tide was at a medium height. |

|

The crewman

in the engine room recalls hearing about 5 thumps coming down

the length of the hull, then the major hit when the object

struck the prop and rudder. I immediately put the engines into

neutral and ran down to the engine room to see what may have

happened. The engineer reported that water was coming in the

lazerette at a high flow rate.

I returned to

the bridge and immediately turned the boat around and headed

back through the 3 bridges toward the Everett marina. When it

became apparent that the flow rate was too high to be maintained

by the existing bilge pumps I selected a muddy beach to run the

boat upon. At the same time I notified the Coast Guard on

Channel 16. There was an immediate reply from the Snohomish

County Sheriff that they could be there in 5 minutes with a

large pump. |

|

|

When they

arrived by boat we immediately started pumping the aft

compartments. We connected a towing line to a second boat and

headed for the Everett Marina. That initial pump reduced the

in-flow to a manageable rate. We were still unable to determine

what was wrong, but could see that it was in the area of the

starboard rudder. When we got to the dock a second pump was

added and that started getting ahead of the in-flow. The Everett

Marina provided a 3rd pump and that reduced the water

level so that I could see the exact problem. |

|

|

|

|

|

|

On deck pump |

On dock pumps |

Milling around |

Plank out the back |

Sunset with 1 pump running |

|

It appeared

that the rudder had hit the object and had kicked astern, but

had immediately snapped back to its normal position. This

action pushed the plank directly behind the rudder post back

about 10”, leaving a 4” by 10” (approximate) hole in the bottom.

Now that I had seen the problem I went over the side into our

small boat with a bath towel and stuffed it in the gaping hole

and that reduced the flow rate by about 80%. With that in place

we continued to stuff rags into the hole from the inside of the

boat.

During the

night we ran one of the gasoline powered pumps to maintain the

flow rate at a safe level. We had a second pump at ready in the

event there was a primary pump failure. I stayed on the boat to

tend the pumps overnight.

At 7:30am

(5-23-07) Philip Nichols, the recommended diver, was contacted

and he was onsite within 30 minutes. He dove and added

additional materials to seal up the leak. This reduced the

flow-rate to a level that the 12v on board pumps could easily

manage.

Our intention

was to be moved to the Everett Shipyard about 5 minutes away for

a quick haul-out to fix the problem, but they refused to take on

the project due to pressing military contracts. They indicated

that they could not possibly get us in the schedule until late

July. |

|

We elected to have the local Vessel Assist move us back

to our normal moorage where we could determine our

alternatives and start working out the problems. So at

08:00 on May 24, 2007, Vessel Assist moved us as

planned. |

|

|

The move did

cause the in-flow to slightly increase. I contacted Philip

Nichols again to come and seal up the hole more permanently now

that we were at a fixed location. He did do that. Because the

towel was extending below the bottom of the planks it took a

combination of plywood and truck inner tube to protect the towel

from any passing debris that may want to rip it out. |

|

|

|

|

|

|

As scheduled

on June 20 at 10:00 I met with Larry Montgomery of

Montgomery

Maritime Survey, on behalf of International Marine

Underwriters at the vessel and discussed the new game plan. We

then agreed that the most practical action was to tow the vessel

to Seattle or Port Townsend for repair since the local yard was

not interested in the work.

After multiple discussions

with Larry and Rick Brenden from

Port Townsend

Shipwrights Co-op we decided to get the boat ready for a tow

to Port Townsend, WA, the west coast Wooden Boat repair capital.

This required getting the bottom totally sealed for the 6 hour

tow. We called in

Global Diving and Salvage, Inc. to epoxy the damaged areas

to secure it from any movement. |

|

|

Tike Hillman, former 83527 crewman

and volunteer brings immense experience with wooden boats, tugs

and Puget Sound contractor knowledge. |

|

|

|

This preparation also included tying off the starboard prop

shaft, tying the rudderpost forward and capping off the fuel

tank vents. |

|

|

|

|

|

|

Tied off shaft |

Rudder post tied to bulkhead |

Fuel tank vents capped off |

|

Star Marine Inc was

selected to provide the tow. They have a tug presence in the

Port Townsend area and are willing to make the trip. I slept

aboard the night of July 17th and they arrived at 06:30, and

they were underway about 07:00 with the high tide at about

07:20. |

|

|

|

|

|

|

Picking us up at Everett |

|

|

Arriving at Port Townsend Bay |

|

|

|

|

At about 12:30 I saw them out in the bay getting rigged for the

last leg into the marina. We tied her up to the long dock at the

entrance to the travelift. |

|

|

The next morning at 08:30 we were scheduled for the haul out

with the 300 ton travelift. Although she only weighs 44 ton, she

was too long to be picked up by the 70 ton lift area. Also I

didn't want the old girl being picked up only the 4 narrow

straps. The 300 ton lift has 6 very wide straps. After a 20

minute fiasco with the Port

of Port Townsend Director of Marine Facilities, Ken Radon,

about not hauling this thing out at his marina, we got back on

track and started the lift. She was moved to the cleaning pad

and pressure sprayed off and then moved to the work area near

the Port Townsend Shipwrights facility. She was blocked and we

got a good look at the damage. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Friday Morning (7-20), at 08:00 we met and looked it over in

detail with the shipwrights. The initial assessment shows that

the starboard prop is folded beyond repair and one blade on the

port prop is dinged. The rudderpost did kick back and stuffed

the plank out the back. That cracked a number of members around

the rudder post internally. The starboard strut also was whacked

and kicked inboard. that damaged the planking below the strut

and cracked the supporting planks internally. The strut does

have a crack at the front edge of the bearing, but that appears

to be an older problem. Wednesday morning (7-25) we will meet

again with the shipwright that will be doing the work for his

assessment of the project. More info then. |

|

|

Wednesday 8-1 Teardown and

Assessment |

|

|

|

|

|

|

|

|

|

|

| Saturday 8-4

New Ribs and Sisters being steam formed |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Monday 8-6

Blocking to support starboard rudder post being constructed |

|

|

|

|

|

|

| During Week of

08-20 More ribs replaced around Stbd center strut. |

|

|

|

|

|

|

|

|

|

|

|

|

Week of 08-27 New planks

prepared and attached. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

Bungs cut on drill press |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

The paint removal and new

application team. |

|

|

|

|

|

|

Hawaiian Chieftain |

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

10-31-07 After a number of delays we are

headed back to the water. |

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

11-03-07 Trip back to Everett |

|

|

|

|

|

| |

|

|

|

|

|

These photos below were taken by

Tom Mateer, a friend of the 83527, at arrival.. |

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

| |

|

|

|

|